EARTH MOTO - HUNCUT

ROYAL ENFIELD 650 interceptor 2021

A foreign customer contacted us with the idea of making a cafe racer out of his brand new Royal Enfield 650. The customer has not only an idea but the whole 3D model based on the precise modeled or scanned frame including the one-piece gas tank and the headlight housing.

I must say the final motorcycle is almost identical to the 3D model.

The tank was at first printed on a 3D printer as a model without the base tunnel and the fitting brackets. The original tank was cut in half horizontally. The inside tunnel was taken as the base of the tank. Then the steel tank was built on the top of this base. The engine is silver painted in original. The engine head cover and the sides of the engine were painted with 2k black engine paint. The initial thought was to keep the engine in the frame. But there were a lot of unused brackets. The whole frame is shaved of these brackets and has two separate inside pans for electronic. After these changes, the frame was powder coated.

The exhaust is made of a 50mm stainless steel tube. The lower bend is made on a bending machine. The top bend is made of tube knee welded at a precise angle to match the 3D model. There are 4 welds on each exhaust sanded down to be invisible. The tube was purged with argon while welding. On the end is fitted a very effective steel muffler. The sound I must say was a pleasant surprise to me. Not a loud but precise crisp sound without ‘plastic bucket farting’. The air filters are DNA brand fitted on the tubes knees welded in an S shape heading to injectors. Because of the total length of the air system, the back filters had to be supported with a bracket bolted to the custom-made seat pan which hides all the electronics including the Motogadget M-unit Blue.

The headlight is LED Koso fitted in custom-made housing. The triple tree clamp was designed from scratch and made of 7000-grade aluminum.

The forks are shortened by 5cm. The rear shocks are new. The original shocks were zinc plated and were already corroded after a couple of kilometers of ride. The spikes were silver. We decided to make them Teflon-plated. It is easy to clean and it is chemical resistant. The soft surface f the spokes is also not prone to chipping from flying gravel.

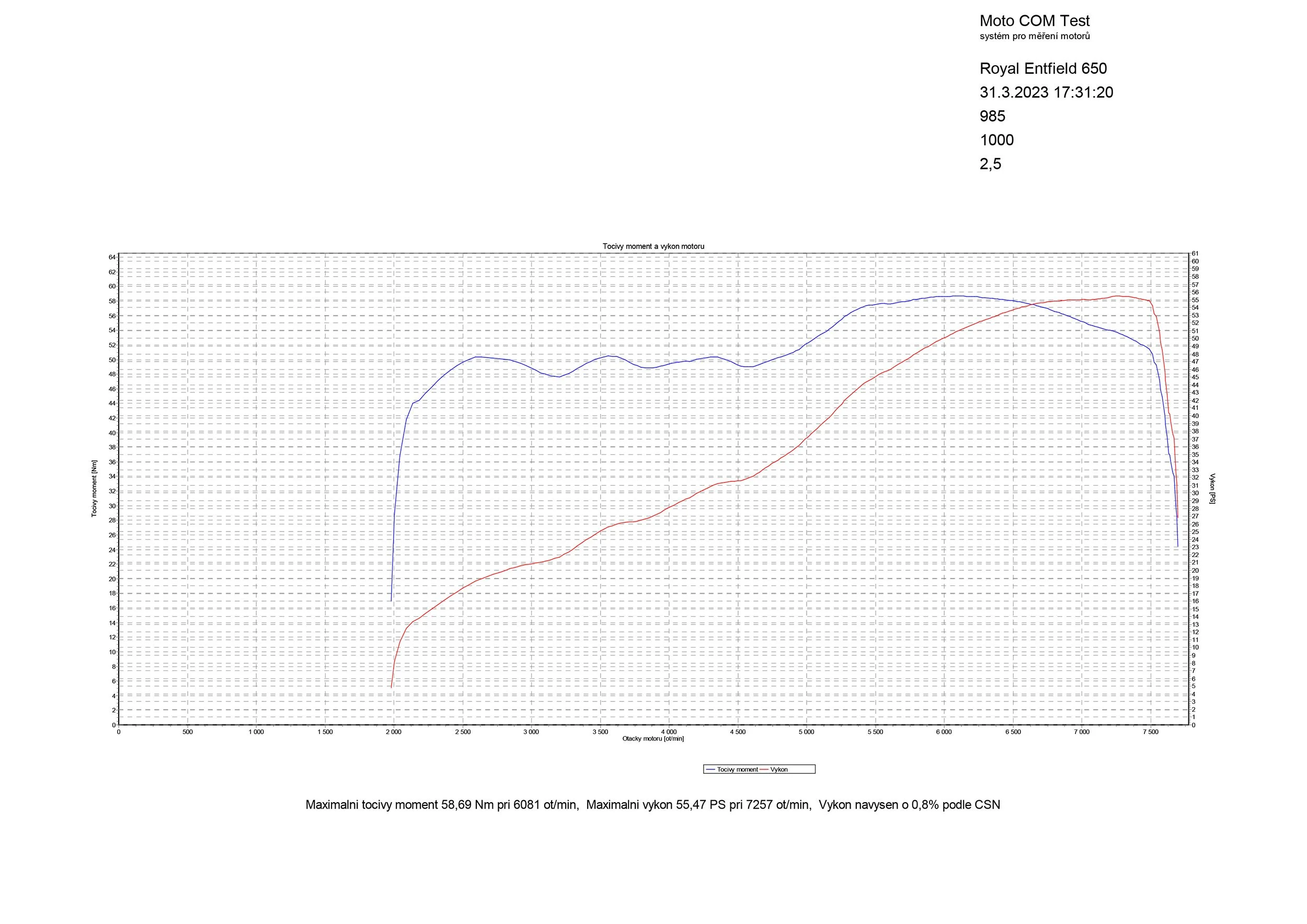

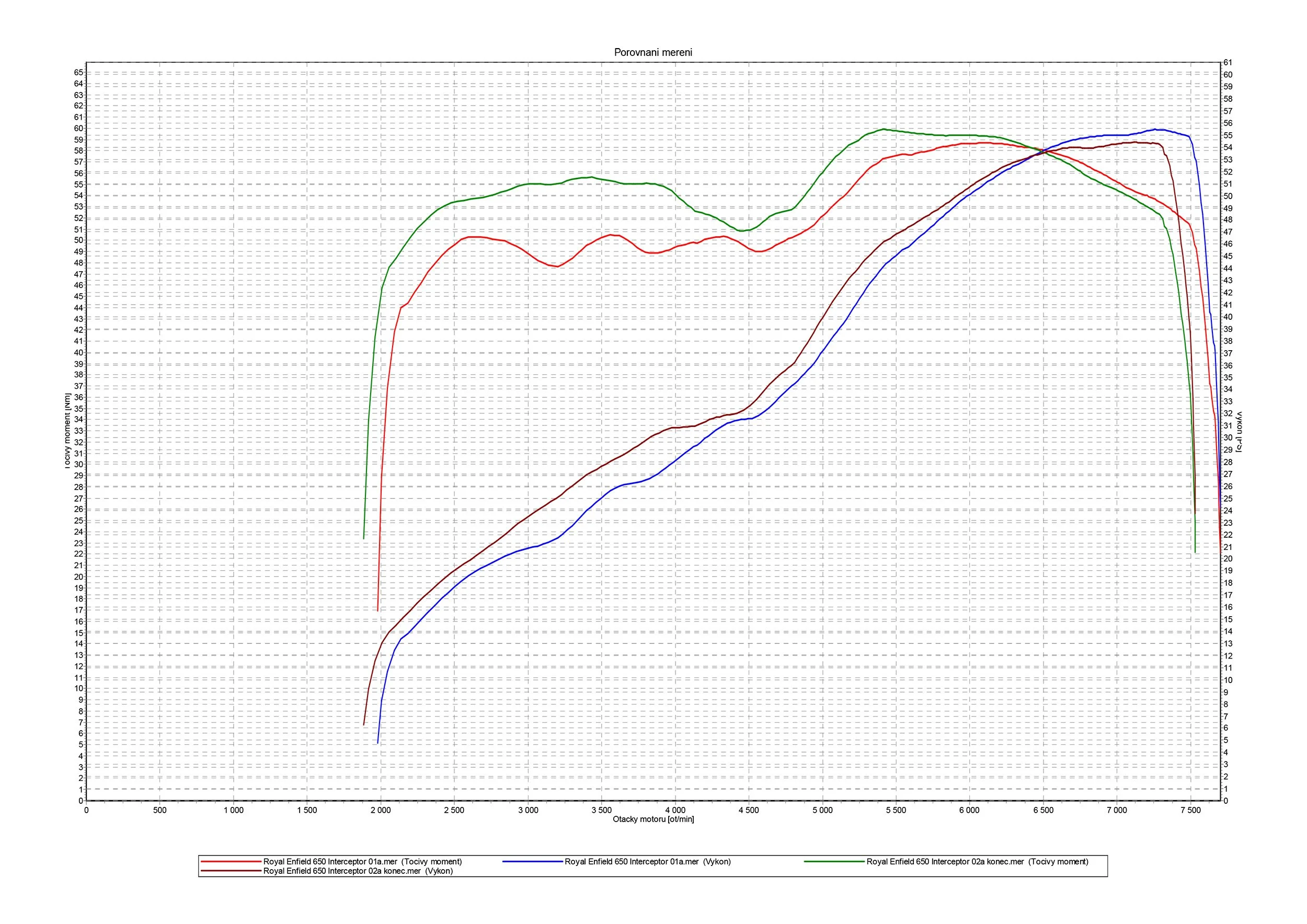

The frame was shortened and fitted with Highsider rear lights. The style of the lights is the same as we used on model Cikula / Bakula but now with aluminum inserts because the tubes were too big to fit the 22mm lights. The original battery was moved behind the engine in a separate box. The bike was taken to a professional to tune the engine and measure the curve of power and torque. The final result is 10 more horsepower which is an impressive number for the 650cc engine.

SPECIFICATION

Frame and swingarm:

- shaved from all the unused brackets

- powder coated frame

- new aluminum footpegs Cognito Moto

- new welded subframe pans

Forks and shock:

- custom made Al 7005 triple tree clamp

- internally shorten forks by 5cm (2 inches)

- new rear shocks

Wheels and steering:

- new Avon Roadmaster II tires

Tank and seat:

- new custom-made steel fuel tank based on a 3D model

- professionally coated using a 2k technology

- custom seat Milita

Engine, gearbox, and transmission:

- parts of the engine painted with 2k engine paint

- new custom-made stainless steel exhausts

- professionally tuned engine with more power

Fuel and air system:

- DNA filters with custom-made headers

Brakes:

- new Discacciati levers

Electric:

- a lot of new outside wiring harness

- Motogadget M-unit Blue with alarm and keyless ignition and many more features

- Velona II speedometer

- pushbutton controls Motogradget

- Highsider, Motogadget and Koso lightning, CE certified